|

|

|

|

#1

|

|||

|

|||

|

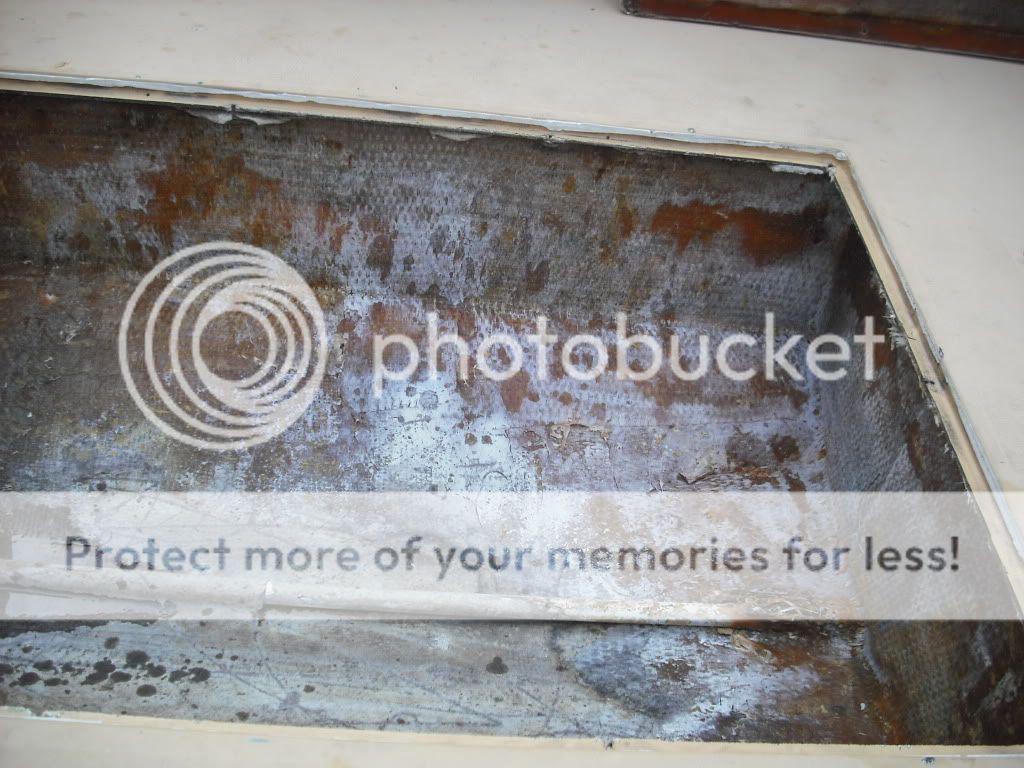

Please note you do NOT need to cut the deck for the tank removal, it was the replacement tank that forced me to cut the deck, the old tank will pull without any cutting, I honestly I was not 100 % sure you now have me thinking :) Until I dug up the picture !

Last edited by nymack66; 04-01-2010 at 07:11 PM. |

|

#2

|

||||

|

||||

|

From my experience on my '84 cuddy (outboard)...You have to remove ALL of the foam from BOTH ends. That gives you room to slide the tank aft, grab the fill elbow, lift and tilt the forward end up. Did it with no help.

As for foam...After you cut and dig out as much as you can, scrape your knuckles til their bloody, you should know that foam comes out with a power washer and a yellow nozzle...like butter.. Those pieces of "butter" will get in your bilge. They float and will move around until they block up the drain holes in the bulkheads....more scraped up bloody knuckles and arms trying to reach all of that stuff! If you foam in the new one, make sure you imediately secure the boards in place to hold the tank down and be sure that the fill and vent elbows will be below the hatch. If you wait too long the expanding foam will raise the tank up. I got lucky. I laid the boards on top of the tank and took a breather..10 minutes later the tank had risen up and pressed the boards to the underside of the deck. My opinion on foaming in aluminum tanks...Wellcraft foamed it in, the one that was there lasted 23 yrs...who am I to mess with that?

__________________

1984 V20 "Express" & 2003 Suzuki DF140 (SOLD!) 2000 GradyWhite 265 Express YouTube/SkunkBoat https://www.youtube.com/channel/UC4F...znGospVOD6EJuw Transom Rebuild https://www.youtube.com/watch?v=EEz94NbKCh0 https://www.youtube.com/watch?v=Oe_ZmPOUCNc |

|

| Thread Tools | |

| Display Modes | |

|

|