|

|

|

|

#1

|

|||

|

|||

|

Took two half hours with a 4 1/2 " angle grinder to bevel and grind through the outer skin. Then only 30 minutes to remove the skin from the rotted mush. WOW the dust is something else. Have some pictures of the project. Will post as soon as I read the"How To" severial times.

Just for information the gel coat and fiberglass on a 1978, V20 Cutty Cabin is right at 7/16 of an inch thick. would have never guessed it would be that thick. That thickness will be a great base for rebuilding the transom. In your collective and learned openion which is the best epoxy filler for me to use along with one 3/4 inch and one 1/2 inch plywood between the inner and outer skin of the transom? Also, what do any of you know about www.epoxyproducts.com? |

|

#2

|

||||

|

||||

|

I have never did a full transom job, But I did know that the glass was thick!! I had to fill my hole when I converted from I/O to the gill bracket.

I used two 3/4 ply's (1 1/2) to make the same thickness? But you say its only 1 1/4 ? Any way what I did was glass the 2 boards toghter and in thur the inside. Then I used matt in layers till I made the hole the same thickness as the rest of the transom. So what do you have to fill? If you fill the transom with the same thickness in ply, you should just have to glass the skin back on right? Just trying to understand in case I ever have to do a hole transom. Can't wait till you post pictures, and the rest of the info!! ;)

__________________

1986 V20  Old Fishermen never die, we just SMELL that way!! |

|

#3

|

||||

|

||||

|

Should be two layers of 3/4" to make that transom? I'd try to have my pieces cut and prepped. You may have to do one piece at a time to get it to make the curve that we have in the transom? Either that, or if working with both pieces use a dozen or so 3/8" thru-bolts with fender washer to pull it all together until it kicks, then go back and patch the holes.

Airslot

__________________

Airslot Airslot's V-20 Gallery |

|

#4

|

|||

|

|||

|

I used two sheets of 3/4 ply that I used west system to join them with a few screws to pull them together I then covered with a thin sheet of fiberglass. I had to put on one section at a time and I believe it was in four sections( when I say one scetion at a time it was secure one add the next) .I had two people helping one mixing the resin and the other helping to put it in. Instead of using thru bolts i drilled holes for wood screws below the water line then any other holes I had for tow cleats, scups etc.. I used a small peice of wood with a wood screw to pull it tight (the small peice of wood is on the out side like a washer). Then I collected all the different clamps I could find and went to town. Places where I used the small peice of wood as washers rub some wax around the out side of the hole because resin will squirt out and the wax will keep it from bonding to outer gelcoat. Using this method you will not damage the outer gel coat. I then came back and drilled out all the thu holes and coated them with west system. I used West System on recommendations from a friend who works on boats its more expensive but he siad don't go cheap on the transom. One other thing is to dry fit everthing first to see which way is best to install the new transom. I hop this helps some.

|

|

#5

|

|||

|

|||

|

Because 3/4 plywood is not really 3/4 of an inch thick believe I can get two sheets in the void.

The reason for the filler question is two fold. One there are areas in the transom which the factory added extra rosin/fillerthat prevents the plywood from fitting snug. Second there are lots of chip outs, drilled holes, etc which must be filled. The question concerning the Epoxy Products Co. is that they have a lot of epoxy products for boats and the prices seem to be lower than other companies. |

|

#6

|

|||

|

|||

|

Pictures would be great on this topic. I always seem to get lost on this topic. So mine is an 1986 with really no access to the transom from the inside. So I would then simply cut the out skin off to get to the wood. Tear out the wood and simply wet/glass in new wood to the inner skin ? Then reseal the out skin to the wood and glass over the cut out pattern ? What about where the transom meets the outer gunnels ?

__________________

|

|

#7

|

|||

|

|||

|

Have attempted seven times to get set up with Photobucket; rejected each time because of their code. Have Kodak Easy Share. Would be glad to E-mail the pictures to someone and they post them.

As for the gunnels. Using a sawsall cut the fiberglass/gelcoat and the outer skin slipped out. The plywood only goes up about an inch under the gunnel. To put a curve in the plywood to match the transom curve, I will place the ends of the plywood about 6 inches off the ground and put a log in the center. I believe, after afew days I will have a curve set in the plywood. Just like standing it up against a wall. |

|

#8

|

||||

|

||||

|

I also have an easyshare account and I tried an experiment.

It did not work, but what you could do is share a gallery and then post a link here. Example, I shared the album with myself and then add the link below after opening the share e-mail. http://www.kodakgallery.com/Slidesho...7p7u6&Ux=0 These pictures are from this past summers vacation with my son and his fiance.

__________________

Bottom's up!!! Bottom's up!!!

|

|

#9

|

||||

|

||||

|

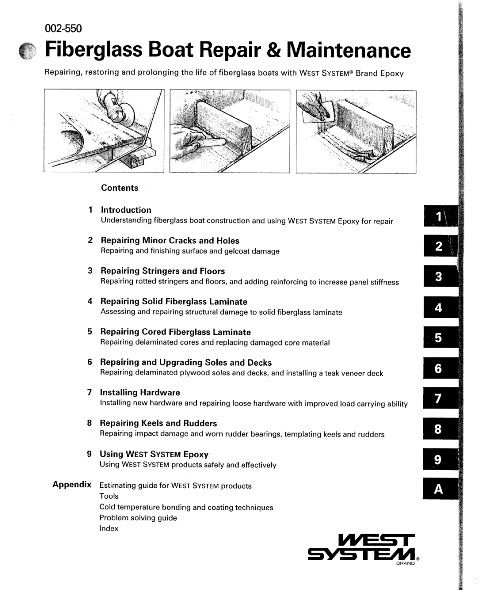

HAMMER, at WEST along the back wall where they have all the glassing supplies,

they have a good book that is a resonable price, It is called "Fiberglass Boat Repair & Maintenance" I am sure it was less than $10.00 Here is a scan of the front cover:

__________________

Bottom's up!!! Bottom's up!!!

|

|

#10

|

||||

|

||||

|

Send them to me, [email protected]

__________________

1986 V20  Old Fishermen never die, we just SMELL that way!! |

|

|

|