|

|

#1

|

||||

|

||||

|

You probably seen my post in the general area about the '79 cuddy I brought home. I figured now that I'm actually working on it now I'd move over here to the repair section.

I knew the transom needed work and hoped it was otherwise solid. Today my wishes were crushed. I cut the cap off of the rear and started gutting the transom. Cap section removed:  Shot of the transom pre demo:  I was quick to see there was not much left of the transom. There was actually one layer of plywood with just a second layer in the raised area you see around the sterndrive hole. Tapping on it with a hammer showed that only near the top was there any structure left. Pulled the inner skin off. Rather easily thankfully:  Port side:  Stbd:  The center section of plywood around the sterndrive was mush. Scraped right out. I then used a flat bar between the rest of the wood and the outer skin and it came off surprisingly easy. Probably 70% of it just came off with majority of the layer of CSM with it. You can tell where you can see the woven roven clearly that it came off good there. The other areas left a layer of plywood. I scraped as much wood off first to lessen the sanding and gumming up of my sanding disc. Here she is with a light sanding over it all. I plan to try and sand all the existing CSM off before reinstalling the transom:  Port:  Stbd:  Now the crummy news. Stringer's are mush. I checked them up to the tank hatch and they are pretty much non existant. So I imagine they'll need replacing all the way up. Not at all what I wanted to find but it is what it is. Just now I have no idea where I'm heading with this project. My very first plan with this boat was to strip it all the way down and rebuild with all composites and make it a center console, skiff type boat. Then I thought just putting a transom in it and running it the way it was sounded good but it appears stringers and I'm sure the deck will need to be re-cored. My next plan is to pull the gas tank and see if the stringers are rotten all the way up. I'm not holding my breath that they aren't. I really am stumped at what to do. Part of me just wants to build a center console out of this one then maybe sell the green boat as I don't see any reason for having 2 center console (the wife doesn't see any reason for 2 boats period). Then again it's a beautiful boat as is. I guess I'll cut the floor out and see where that takes me. Either way I'm looking at a lot of time and money but in the end I will have a rock solid, non wood boat.

__________________

Current boat(s): 1985 V-20 Cuddy/ 470 IB/OB 1972 Egg Harbor 38’ Sedan/ 454 Crusaders |

|

#2

|

||||

|

||||

|

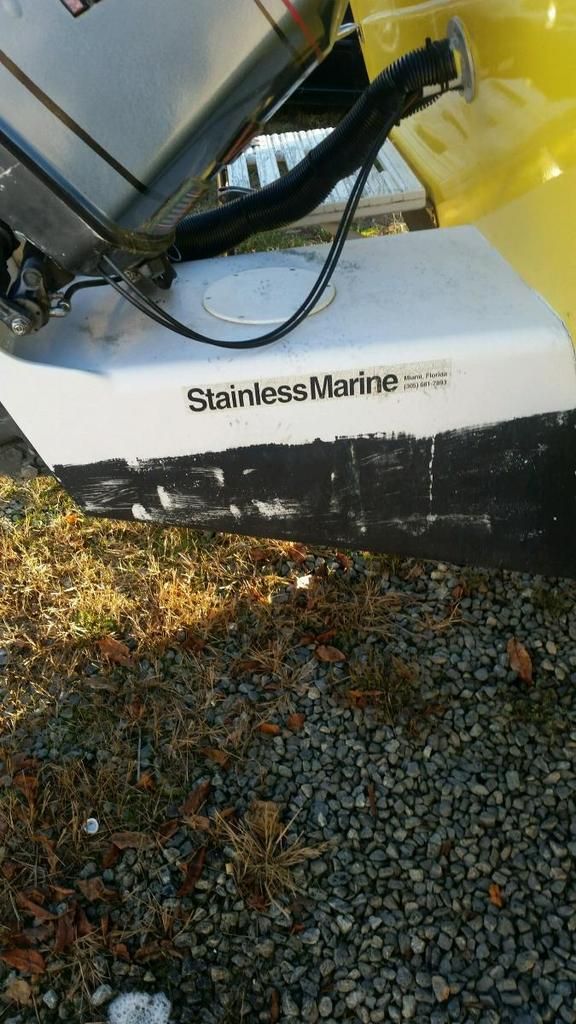

I read online about measuring the transom angle with a carpenters square. So I followed that and found it to have a 13* transom. I found a Stainless Marine bracket for $400 I'm just waiting for it to be removed so I can check that boat and make sure it'll work for me. I read a few places that you can have a +/-2* window that tilt and trim will take up. I know the boat is a Proline but not sure what model. If it has a 11-15* transom it should work for me.

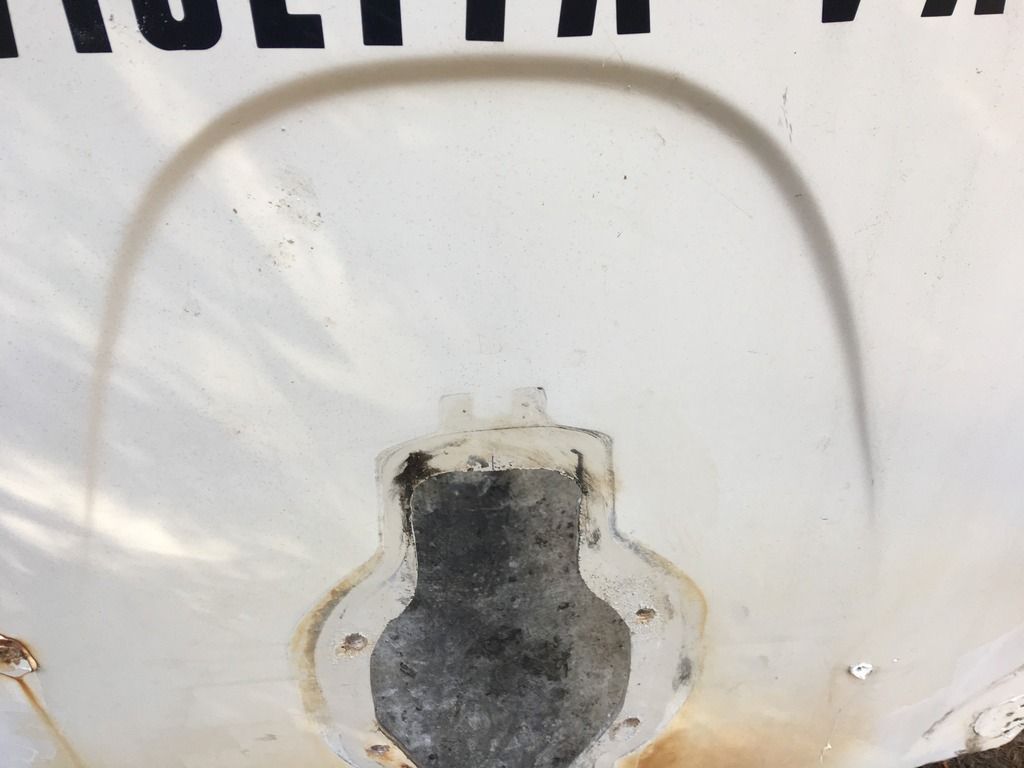

No matter what direction I go with this boat I need to figure out how I'm going to lay the transom in. I plan on going with composite (Coosa I assume is my best option??) however the transom is not only curved like all V-20's but it has a kind of pop out. So I won't be able to lay 1 solid piece in the transom, even if I notch it to make 3 "separate" surfaces. Above the pop out will be 1/2" from touching the core material. Here's some pics. Let me know what route you'd guys would take. Originally they had the popped out section as 2 seperate pieces of wood. Then the rest of the transom arched around it and it was filled in with some sort of filler. I don't really like the idea of completely separated pieces in a transom.

__________________

Current boat(s): 1985 V-20 Cuddy/ 470 IB/OB 1972 Egg Harbor 38’ Sedan/ 454 Crusaders |

|

#3

|

||||

|

||||

|

Here's the bracket I found. Waiting for it to get removed. Priced them at $1300 new so $400 for this one seems good enough for me.

__________________

Current boat(s): 1985 V-20 Cuddy/ 470 IB/OB 1972 Egg Harbor 38’ Sedan/ 454 Crusaders |

|

#4

|

|||

|

|||

|

You're not wasting any time tearing into this one!

__________________

1973 Mako 20' Center Console 1984 Wellcraft V20 Cuddy 1977 Wellcraft V20 Center Console 1975 Wellcraft V17 Center Console 1964 16' Super Skeeter with 55Lb thrust Motorguide Trolling Motor 1985 Glastron HPV-175 - sold 1984 Wellcraft 180 Fisherman - sold 1973 Mako 17' Angler - sold 1972 Mako 17' Standard - sold 1972 Mako 19' Center Console - sold Always looking for the next one. |

|

#5

|

|||

|

|||

|

Boy I wish I could tackle a job like that Keep the pics coming as you move ahead,

__________________

love to fish |

|

#6

|

||||

|

||||

|

Having boat withdrawals. My green boat has been at other people's places for the past 3 months. I just needed to cut into something.

Quote:

Also something weird with this boat. The bottom of drain hole is about 2" off the bottom of the hull. This thing holds a lot of water unless I lift the tongue 4' in the air. May have to relocate that as well. The bottom of this plug is where the top of my green boat is. Weird to be that different for the same year.

__________________

Current boat(s): 1985 V-20 Cuddy/ 470 IB/OB 1972 Egg Harbor 38’ Sedan/ 454 Crusaders |

|

#7

|

||||

|

||||

|

Had a little time today between work and kids hockey practice so I pulled the tank hatch off, which was not sealed or fastened at all. The tank was foamed in nice and thick. Of course the foam on top of the tank was completely saturated in water and or fuel. I got most of the foam off the top of the tank. I was mostly just curious of what the tank looked like. I can imagine it's going to be a nightmare releasing the tank from the foam.

I think I've come to conclusion to keep this hull the cuddy cabin. At this point it's obvious the stringers and floor are gone. Floor has some solid spots but many soft ones too. I'm assuming this may be from the parquet core they used. It seems to have worked properly, only rotting the pieces that had water intrusion. But it seems it has many places for the water to get in. I was going to cut the floor out tonight but I am now debating trying to get the whole cap off. Just trying to figure out how to do it. It seems stripping as much as I can off the cap to lighten it up. It sucks that I cut the rear of the cap off now that I'm planning on doing this but hey, it is what it is. Planning on removing the cap this weekend.

__________________

Current boat(s): 1985 V-20 Cuddy/ 470 IB/OB 1972 Egg Harbor 38’ Sedan/ 454 Crusaders |

|

#8

|

|||

|

|||

|

Thomas, for what it's worth, I saw "Ship Shape TV" Saturday and they were discussing a product that dissolved the foam. It came from "Fiberglass Coatings Inc". Maybe that might make the the tank removal easier. The number for the St. Pete store is 800-272-7890.

__________________

An adventure is a disaster that fails to kill you!! 1987 V20 Cuddy 175 Yamaha SOLD 1996 V21 Cuddy 200 OceanRunner SOLD 1994 V21 Cuddy 150 Mercury SOLD |

|

#9

|

||||

|

||||

|

Quote:

Had about 45 minutes of daylight after work do I pulled the rest of the rubrail off. Then went ahead and removed the windshield. Hopefully tomorrow I can get the helm and all of the wiring out of the boat. I'm trying to make actually pulling the cap an easy, snag free process. But I seriously doubt it'll go like that. Once I get the cap off I plan on reinstalling the part I cut off while it's out since I'll be able to glass the back with nothing in the way. So opinion time. The stringers seem to be 100% mush. Has anyone thought about filleting the top of the stringers off. Digging out the core and pouring a product like arjay or nida core?

__________________

Current boat(s): 1985 V-20 Cuddy/ 470 IB/OB 1972 Egg Harbor 38’ Sedan/ 454 Crusaders |

|

#10

|

||||

|

||||

|

Quote:

Get an electric chain saw.... Can't wait to see how you get the cap off. I need ideas...

__________________

1984 V20 "Express" & 2003 Suzuki DF140 (SOLD!) 2000 GradyWhite 265 Express YouTube/SkunkBoat https://www.youtube.com/channel/UC4F...znGospVOD6EJuw Transom Rebuild https://www.youtube.com/watch?v=EEz94NbKCh0 https://www.youtube.com/watch?v=Oe_ZmPOUCNc Last edited by SkunkBoat; 11-10-2016 at 09:01 PM. |

|

| Thread Tools | |

| Display Modes | |

|

|