|

|

|

|

#1

|

||||

|

||||

|

I would think to go with the same setup for a transom with a bracket of 2 layers of 3/4" ply. The one thing I would do would be to have an aluminum or stainless backer plate made to bolt the bracket to on the inside. Whomever you buy your bracket from should be able to tell you how large of an area you will need to distribute the force across.

I have a piece of aluminum c-channel that the bottom bolts of my motor bolt through. Because of the curvature of the transom I laid out a thick pad of thickened resin, covered it with saran wrap and mashed the channel into it. Once it cured I peeled the saran wrap off and sanded down the resin that squeezed out. This gave me a perfectly flat area that the c-channel rests against. http://www.thehulltruth.com/boating-...storation.html

__________________

81 V20 1996 200 Ocean Pro |

|

#2

|

|||

|

|||

|

Thanks

Awesome build by the way. So you used compsite board? |

|

#3

|

||||

|

||||

|

Thanks, was alot of fun. I only used composite core material on the deck and hatches. There is some pretty neat stuff out there that can used on a transom but I wasn't aware of them when I started in on my project.

__________________

81 V20 1996 200 Ocean Pro |

|

#4

|

|||

|

|||

|

Tartuffe

For composite board dose it have to be infused vacuum bagged? Or whatever the proper terminology is? Doing research and it looks like awesome stuff. Did you start your rebuild onthe exterior of the hull? How did you flip it? Still have your support? Sorry for so many questions but I really appreciate the help! |

|

#5

|

|||

|

|||

|

The gelcoat is also completely shot. . I've started exterior sanding and hit the glass in a few spots.. grinding down all cracks. Does the gelcoat all need to come off? 2hrs sanding didn't get a lot done.. I'll post some pics in the am

|

|

#6

|

||||

|

||||

|

All the gel coat doesn't need to come off.

Going back with paint will be a whole lot easier.

__________________

1985 Wellcraft V-20, Evinrude ETEC 150: SOLD 1979 Marine Trader 44, twin Ford Lehman 120s 2006 Panga 14, Tohatsu 20 |

|

#7

|

|||

|

|||

|

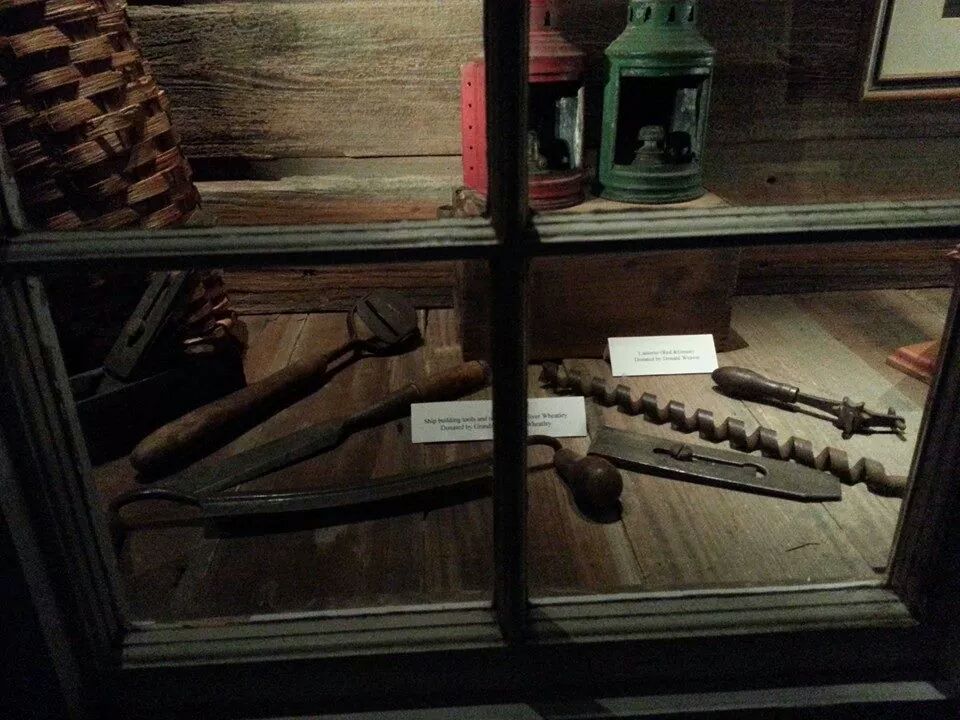

It's in the blood, Picture of my great grandfathers ship building tools. My dad donated them to our local maritime museum.

Pics of the gelcoat, where I have sanded and alot more to go    Next couple pics are for fairing related questions. How thick can fairing be on its own? At what thickness should i be adding CSM?   This last pic has me concerned. this is the top where the outter and inner skin match up. Looks like it's resin starved? recomendations on fixing?   Bored at work  Thanks again for your input & help!! Last edited by brywheat; 07-12-2014 at 08:06 PM. |

|

#8

|

||||

|

||||

|

Quote:

__________________

81 V20 1996 200 Ocean Pro |

|

#9

|

||||

|

||||

|

The pic of the straightedge against the gunnel showing the wave in the hull, that will come out with the construction of the cap. Take it easy with the sanding. Sanding sucks and damn its enticing to go with a grit to actually make some progress like an 80 or even 60. In reality you should probably use a chemical stripper and a 200 grit. The more of that gelcoat you save the better. Gelcoat is a waterproof coating that protects the fiberglass from water intrusion. Its kind of like an insurance policy.

Most of your fairing will be with high-build primers and a longboard. Takes many coats but the lighter the color of the finished product, the more forgiving it is. These boats are not incredibly fair to begin with. I wouldn't be too worried with that. Few sanded coats of high build primers with some longboarding and it is what it is. We can talk about that after you get the structural fixed.

__________________

81 V20 1996 200 Ocean Pro |

|

| Thread Tools | |

| Display Modes | |

|

|