|

|

#1

|

||||

|

||||

Here's a oak handle I made for my dads cleaver that he has kept by the fire place in the house since I was a baby. He use it to split cedar and other wood for kinlin. I noticed it missing from the house and I asked him were it was. He said the handle broke of. So as any son would do I wanted to see his cleaver by the fire place again, so I made the ole man a handle today. It's one piece oak and I even put his finger sizes in the handle. I gave it to him today and he got a little emotional. Love ya pop!!! Last edited by Kracker Jack; 02-17-2013 at 08:41 PM. |

|

#2

|

||||

|

||||

|

There ya go, son. done a good thing.

__________________

Willy 1986 V20 Old School 1992 V20 1992 150 Yamaha 1997 HydraSport 2250 Vector 2009 17' G3 Outfitter "G Spot" http://www.youtube.com/watch?v=TDebw...eature=related "I won't be wronged, I won't be insulted and I won't be laid on a hand on. I don't do these things to others and I require the same from them" JW |

|

#3

|

||||

|

||||

|

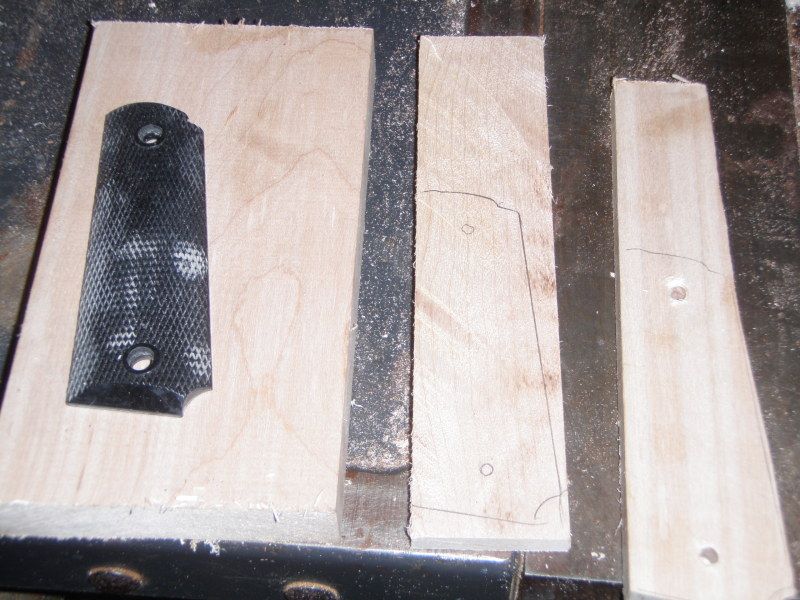

pretty cool, I've been playing with making grips for my 1911, I've made two sets out of maple, then I put it in the holster and discovered they didn't match, so its off to find another wood, I've got some sun bleached mahogany and some teak to try, we'll see what it looks like

|

|

#4

|

||||

|

||||

|

Quote:

|

|

#5

|

||||

|

||||

|

I have 2 nice pieces of rose wood and a nice length of black iron wood. But I'm pretty helpless in the carving dept. I'd love to make a set of grips for my combat commander, but I'm afraid of ruining the wood. <sigh> Maybe some day.... (It's funny, cause I can use a milling machine and a lathe and make damn near any part I want out of metal... but wood scares the crap outta me)

__________________

1987 V20 w/1987 150HP Yamaha on a Shoreland'r Trailer 1978 16.5 Airslot w/1996 120HP Force on a Four Winns trailer 1996 V21 w/1993 200HP Mercury on a Shoreline Trailer All towed by a 5.7L Hemi Durango. If God didn't have a purpose for us we wouldn't be here, so Live simply, Love generously, Care deeply, Speak kindly. (Leave the rest to God)  Silence, in the face of evil, is itself evil. Not to speak is to speak, not to act is to act. God will not hold us guiltless. |

|

#6

|

||||

|

||||

|

cut out pieces of wood 7 inches by 2 inches by 1/4. Draw the outline of the grip panel on the wood, using one side as the final straight edge

Drill the pilot holes for the grip screws. Leave the extra on length so you can put it in a vise to shape it. I used a band saw to cut the outline of the panel, leaving it attached at teh top. The cheese grater file is your friend on this. Once you have it shaped like you want, smooth it out with a soft sanding block and sandpaper(240 works well). I still haven't figured out a good way to make brass inserts for the screws. I've done three sets out of the maple so far. teh biggest problem I found is once I get them looking good, I keep screwing with them till i mess one panel up, then have to start again. I'm going to try some checkering once I get the files from brownells

|

|

#7

|

||||

|

||||

|

Quote:

|

|

#8

|

||||

|

||||

|

that's about 6 coats of semi gloss over the maple. I've moved on and the next set will be teak. I got started on this idea when i saw a kimber with bone grips, i researched it a bunch, found a place that had bone and figured i needed to practice before I tried the bone, somewhere along the way, I got reasonable and thought about me having to hold something white, it would stay that color for about 10 seconds, then it would have big dirty paw prints on it, so I started playing with different wood. My sister runs a millwright shop near Raleigh, she gave me some nice scraps to start with

|

|

#9

|

||||

|

||||

|

Kracker - a vintage cleaver of that quality needs to be swinging a butt atop a maple butcher block .. . . . . or to spatchcock a bird.

They don't make em like that anymore.

__________________

1994 Wellcraft V21 |

|

#10

|

||||

|

||||

|

Oh....Thats not the good ones!!!! he has 2 other cleavers that are bad to the bone!!! we use to chop our hogs

|

|

|

|